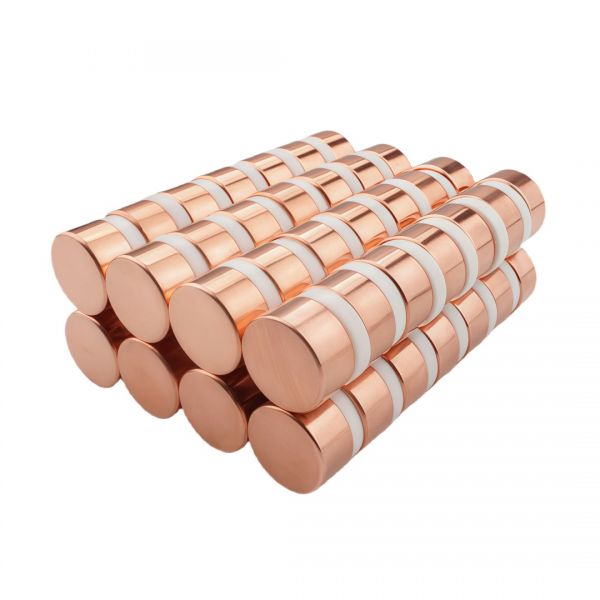

D30x2mm Disc Magnet With Black Epoxy Plating Disk Magnets

Specification

| Properties | Br | HcB | HcJ | (BH)max | Temp. Coef. | Tw | |||||

| Grade** | Typical mT | Typical gauss | min kA/m | min oersteds | min kA/m | min oersteds | min kA/m | min oersteds | α(Br) %/°C | α(HcJ) %/°C | max °C |

| N35 | 1210 | 12100 | 860 | 10800 | 955 | 12000 | 283 | 35 | -0.12 | -0.618 | 80 |

| N35X | 1210 | 12100 | 860 | 10800 | 955 | 12000 | 283 | 35 | -0.11 | -0.618 | 80 |

| N38 | 1260 | 12600 | 860 | 10800 | 955 | 12000 | 306 | 38 | -0.12 | -0.618 | 80 |

| N40 | 1285 | 12850 | 923 | 11600 | 955 | 12000 | 318 | 40 | -0.12 | -0.618 | 80 |

| N42 | 1315 | 13150 | 860 | 10800 | 955 | 12000 | 334 | 42 | -0.12 | -0.618 | 80 |

| N45 | 1350 | 13500 | 860 | 10800 | 955 | 12000 | 350 | 44 | -0.12 | -0.618 | 80 |

| N48 | 1400 | 14000 | 836 | 10500 | 875 | 11000 | 374 | 47 | -0.12 | -0.618 | 80 |

| N50 | 1425 | 14250 | 836 | 10500 | 875 | 11000 | 390 | 49 | -0.12 | -0.618 | 80 |

| N52 | 1450 | 14500 | 836 | 10500 | 875 | 11000 | 406 | 51 | -0.12 | -0.618 | 60 |

| N33M | 1175 | 11750 | 836 | 10500 | 1114 | 14000 | 267 | 34 | -0.12 | -0.595 | 100 |

| N35M | 1210 | 12100 | 868 | 10900 | 1114 | 14000 | 283 | 35 | -0.12 | -0.595 | 100 |

| N35MX | 1210 | 12100 | 868 | 10900 | 1114 | 14000 | 283 | 35 | -0.11 | -0.595 | 100 |

| N38M | 1260 | 12600 | 899 | 11300 | 1114 | 14000 | 307 | 39 | -0.12 | -0.595 | 100 |

| N40M | 1285 | 12850 | 923 | 11600 | 1114 | 14000 | 322 | 40 | -0.12 | -0.595 | 100 |

| N42M | 1315 | 13150 | 955 | 12000 | 1114 | 14000 | 338 | 42 | -0.12 | -0.595 | 100 |

| N45M | 1350 | 13500 | 971 | 12200 | 1114 | 14000 | 354 | 44 | -0.12 | -0.595 | 100 |

| N45MX | 1350 | 13500 | 971 | 12200 | 1114 | 14000 | 354 | 44 | -0.11 | -0.595 | 100 |

| N48M | 1395 | 13950 | 995 | 12500 | 1114 | 14000 | 378 | 48 | -0.12 | -0.595 | 100 |

| N30H | 1105 | 11050 | 796 | 10000 | 1353 | 17000 | 235 | 30 | -0.12 | -0.572 | 120 |

| N33H | 1175 | 11750 | 836 | 10500 | 1353 | 17000 | 267 | 34 | -0.12 | -0.572 | 120 |

| N35H | 1210 | 12100 | 868 | 10900 | 1353 | 17000 | 283 | 35 | -0.12 | -0.572 | 120 |

| N38H | 1260 | 12600 | 899 | 11300 | 1353 | 17000 | 307 | 39 | -0.12 | -0.572 | 120 |

| N38HX | 1260 | 12600 | 899 | 11300 | 1353 | 17000 | 307 | 39 | -0.11 | -0.572 | 120 |

| N40H | 1285 | 12850 | 923 | 11600 | 1353 | 17000 | 322 | 40 | -0.12 | -0.572 | 120 |

| N40HX | 1285 | 12850 | 923 | 11600 | 1353 | 17000 | 322 | 40 | -0.11 | -0.572 | 120 |

| N42H | 1300 | 13000 | 955 | 12000 | 1353 | 17000 | 330 | 41 | -0.12 | -0.572 | 120 |

| N45H | 1350 | 13500 | 971 | 12200 | 1353 | 17000 | 354 | 44 | -0.12 | -0.572 | 120 |

| N45HX | 1350 | 13500 | 971 | 12200 | 1353 | 17000 | 354 | 44 | -0.11 | -0.572 | 120 |

| N48H | 1390 | 13900 | 1011 | 12700 | 1273 | 16000 | 378 | 48 | -0.12 | -0.572 | 120 |

| N30SH | 1125 | 11250 | 811 | 10200 | 1592 | 20000 | 243 | 31 | -0.12 | -0.549 | 150 |

| N30SHZ | 1125 | 11250 | 804 | 10100 | 1592 | 20000 | 243 | 31 | -0.10 | -0.549 | 150 |

| N33SH | 1175 | 11750 | 844 | 10600 | 1592 | 20000 | 267 | 34 | -0.12 | -0.549 | 150 |

| N33SHX | 1175 | 11750 | 844 | 10600 | 1592 | 20000 | 267 | 34 | -0.11 | -0.549 | 150 |

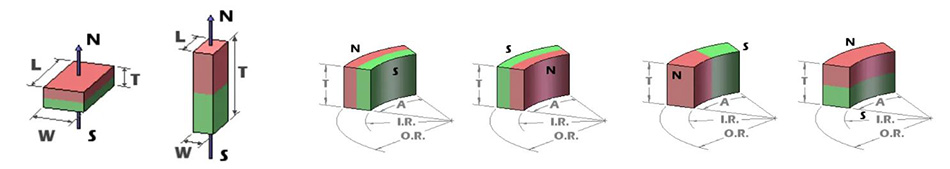

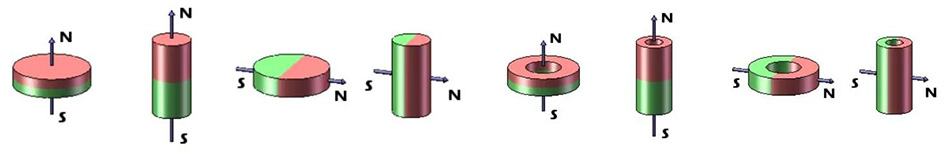

Magnetization Direction

Coating

Why do magnets need to be plated?

Oxidization - Rust:

NdFeB magnets will oxidize(rust) if left exposed. When a plating wears down or cracks, the exposed area will oxidize, the oxidized area will lose its strength. Then magnet will lose some structural integrity and become more susceptible to breakage.

Durability:

Permanent magnet substrate is brittle. A multilayered metal plating like nickel or zinc improves the magnets resistance to chipping and wear, particularly around corners.

Harsh Environments:

Platings vary in their tolerance of different harsh chemicals and abrasion. Salt and humidity in regions near the ocean are commonly overlooked when selecting a plating. Be sure to consider the magnets environment when selecting a plating.

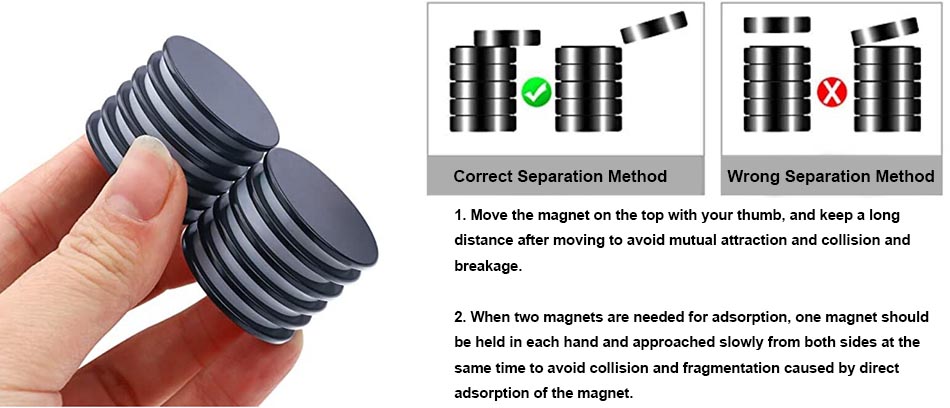

How to use magnet safely

Application Industries

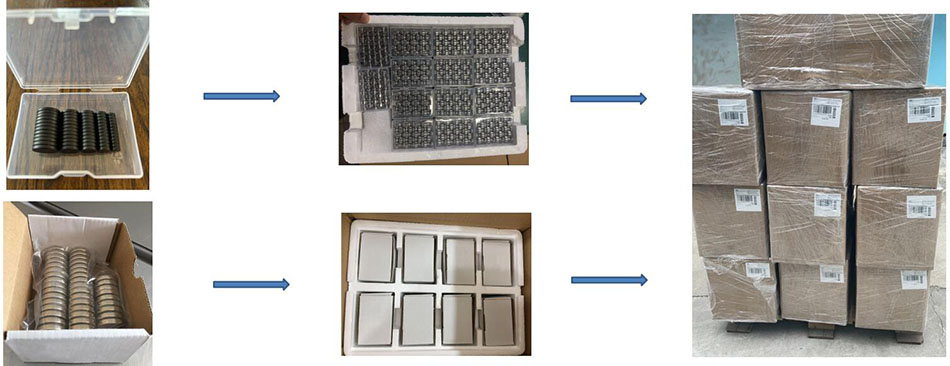

Package